Kratos Glass: Redefining Military Protection with Advanced Bulletproof and Laminated Glass Technologies

In today’s rapidly shifting geopolitical landscape, the defense industry faces unprecedented challenges. From asymmetric warfare to evolving urban conflict zones, threats are more diverse, unpredictable, and technologically advanced than ever before. In this context, the demand for materials that not only save lives but also enhance mission efficiency has grown significantly. Transparent armor, particularly bulletproof glass, bullet resistant glass, and laminated glass, has emerged as a critical technology bridging visibility with protection.

At the forefront of this innovation stands Kratos Glass, a global leader in supplying certified, high-performance glass solutions for armored vehicles, naval craft, and fixed defense installations. By combining clarity, structural strength, and design flexibility, Kratos delivers products that meet the stringent requirements of modern militaries. This article explores the role of transparent armor in defense, compares it with traditional protection materials like steel, analyzes global market trends, and explains why Kratos Glass is uniquely positioned to lead the future of military-grade transparent armor.

Understanding Bulletproof, Bullet Resistant, and Laminated Glass

To appreciate the importance of glass solutions in defense, it is essential to understand the distinctions between commonly used terms:

Bulletproof Glass (Ballistic Glass):

Often used interchangeably with “bullet resistant glass,” this refers to multi-layered transparent materials engineered to withstand projectile impacts. While no glass is truly “bulletproof” against all threats, ballistic glass is rated to stop specific calibers and velocities, offering critical life-saving protection.

Bullet Resistant Glass:

This term emphasizes resistance levels defined by standards (such as NIJ, UL 752, EN 1063). A panel may be rated for handgun rounds, rifle fire, or even armor-piercing projectiles. The resistance level is matched to the mission requirement.

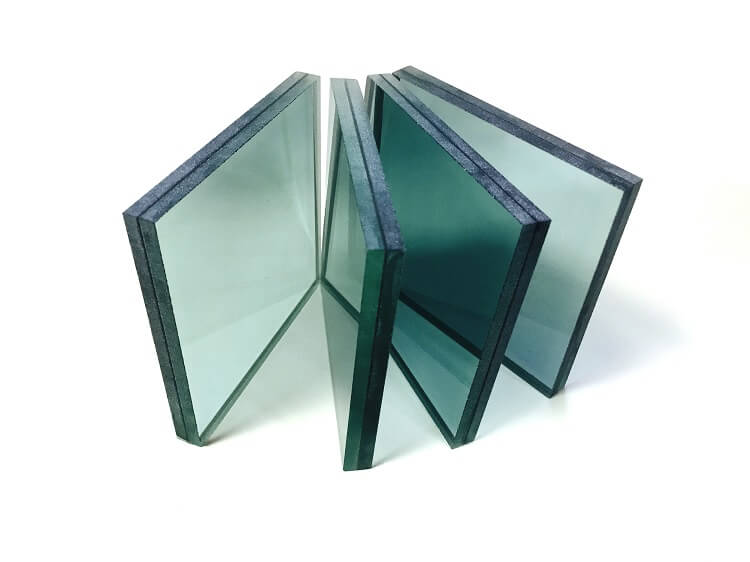

Laminated Glass:

Unlike ordinary glass, laminated glass sandwiches multiple sheets with interlayers such as polyvinyl butyral (PVB), ethylene-vinyl acetate (EVA), or polycarbonate. These interlayers absorb impact energy, prevent spalling (the dangerous spray of fragments inside a vehicle), and maintain structural integrity even if outer layers are compromised.

Together, these technologies enable transparent armor that balances visibility, durability, and protection across a wide spectrum of threats.

Military Applications of Transparent Armor

The military use of bullet resistant and laminated glass spans a wide array of platforms and installations. Its integration is not just a matter of safety—it directly impacts mission effectiveness.

-

Armored Vehicles (Cars, Trucks, APCs):

Transparent armor is indispensable for driver cabins, passenger compartments, turrets, and windshields. Without clear visibility, maneuverability and situational awareness would be severely compromised. -

Naval Craft and Patrol Boats:

Glass panels are used in bridges, observation decks, and control areas to protect personnel from small arms fire and shrapnel. In littoral and riverine operations, such solutions are critical where ambushes and asymmetric attacks are common. -

Fixed Installations and Guard Posts:

Observation posts, command centers, missile silos, and checkpoints require transparent armor to monitor activity while ensuring protection from direct fire or blasts. -

Specialized Defense Equipment:

Transparent glass finds applications in periscopes, gunports, vision blocks, and even drone control centers where protected visibility is essential.

These applications highlight how glass-based armor solutions have become indispensable to modern defense strategies.

Why Glass? The Benefits Compared to Other Materials

For decades, steel has dominated military armor applications. However, the introduction of transparent armor created a paradigm shift by merging visibility with safety.

Advantages of Glass-Based Solutions

-

Optical Clarity:

Maintaining a distortion-free view is crucial. Laminated bulletproof glass designed by Kratos achieves exceptional transparency, ensuring troops can react quickly in combat scenarios. -

Design Flexibility:

By adjusting glass thickness, interlayer type, and heat treatment, manufacturers can tailor panels for specific protection levels without overburdening the platform. -

Weight and Cost Efficiency (Optimized):

Hybrid solutions such as glass-clad polycarbonate and transparent ceramics allow significant weight reductions compared to traditional all-glass armor, while still maintaining protection. -

Low Electromagnetic Signature:

Unlike steel, glass solutions do not interfere with radar or electromagnetic signals, offering tactical advantages. -

Integration with Aesthetics and Ergonomics:

For cockpits, vehicles, and observation areas, glass allows design harmonization without sacrificing safety.

Limitations and Trade-offs

-

Thickness and Weight:

Stopping higher-caliber rounds requires thicker laminates, which add bulk and affect vehicle performance. -

Cost:

Advanced interlayers and transparent ceramics raise costs compared to steel. -

Durability and Maintenance:

Scratches, UV degradation, or multiple impacts can reduce effectiveness, requiring careful lifecycle management.

Ultimately, while steel and ceramics remain indispensable for opaque armor applications, glass delivers irreplaceable value wherever visibility is mission-critical.

Comparative Material Analysis: Glass vs Steel vs Ceramics vs Hybrids

The defense industry constantly seeks balance between protection, weight, cost, and visibility. Each material has strengths and weaknesses:

-

Steel Armor:

-

Pros: Extremely durable, cost-effective, proven for decades.

-

Cons: Heavy, opaque, increases fuel consumption, limits mobility.

-

-

Transparent Ceramics (e.g., ALON, Spinel):

-

Pros: Harder than glass, lighter, superior multi-hit resistance, excellent abrasion resistance.

-

Cons: High manufacturing costs, limited availability of large panels.

-

-

Hybrid Composites:

-

Pros: Combine glass, ceramics, and polycarbonate to optimize weight and strength. Provide spall resistance and superior optical clarity.

-

Cons: Complex to manufacture, expensive compared to standard glass.

-

-

Glass-Clad Polycarbonate (GCP):

-

Pros: High toughness, lightweight, effective at reducing fragmentation.

-

Cons: Limited UV durability, potential optical distortion if not engineered properly.

-

The trend is moving toward hybrid solutions, where transparent ceramics or polycarbonates are combined with laminated glass to deliver lighter, stronger, and more durable armor systems.

Innovation in Transparent Armor: The Case of CERALITE and Beyond

One of the most exciting developments in transparent armor is CERALITE, developed with ceramic integration. Compared to conventional laminated glass:

-

Weight and Thickness Reduction: Over 50% lighter and thinner for equivalent protection.

-

Enhanced Light Transmission: Better optical clarity even at high ballistic resistance levels.

-

Superior Multi-Hit Capability: Withstands repeated impacts without catastrophic failure.

-

Improved Integration: Slimmer panels reduce the need for bulky frames, aiding vehicle design.

For armored vehicles, where every kilogram impacts fuel efficiency, payload, and mobility, such innovations are game changers.

Global Market Trends in Military Transparent Armor

The global transparent armor market is experiencing robust growth, driven by both defense and civilian security needs.

-

Market Size & Growth: According to industry reports, the transparent armor market is projected to exceed USD 12 billion by 2030, with a CAGR of 7–9%.

-

Defense Spending: Rising geopolitical tensions in Eastern Europe, the Middle East, and the Asia-Pacific have accelerated investment in armored vehicles and naval assets.

-

Civil-Military Dual Use: Beyond military, demand is rising in embassies, VIP vehicles, and critical infrastructure, further fueling the market.

-

Material Shift: There is a clear transition from traditional glass laminates to hybrid composites and transparent ceramics, reflecting a push for lighter, stronger solutions.

This growth highlights the importance of innovation and leadership from companies like Kratos Glass.

What Makes Kratos Glass Unique?

In a crowded market, Kratos Glass distinguishes itself through a combination of engineering excellence, global reach, and customer focus.

-

Certified Quality:

Kratos’ products meet international standards (NIJ, UL, EN), ensuring compliance with military and government specifications. -

Global Supply Chain:

With partnerships across continents, Kratos delivers timely solutions to armored vehicle manufacturers, naval shipbuilders, and defense ministries. -

Innovation Leadership:

Investments in hybrid technologies, improved interlayers, and transparent ceramic integration keep Kratos at the cutting edge. -

Customization:

Every defense platform has unique requirements. Kratos works closely with clients to deliver tailored glass thicknesses, laminates, and treatments. -

Sustainability and Lifecycle Management:

Kratos incorporates UV-resistant coatings, anti-scratch layers, and field-repair options to extend the lifecycle of its products, reducing long-term costs.

Strategic Importance of Transparent Armor

In modern warfare, survival depends not only on firepower but also on protection and awareness. Transparent armor allows soldiers, sailors, and security personnel to see and react without compromising safety. The ability to balance protection with mobility—lightweight designs, high clarity, and durability—is crucial in high-stakes environments.

Kratos Glass recognizes this strategic importance. By pushing the limits of material science, it ensures that transparent armor does more than stop bullets: it enhances mission performance, reduces logistical burdens, and provides long-term reliability under battlefield conditions.

Conclusion: The Future of Military Glass Solutions

As global threats evolve, so must the materials that protect frontline personnel. Bulletproof glass, bullet resistant glass, and laminated glass will remain indispensable to military operations, bridging the gap between visibility and protection. With advancements in hybrid composites and transparent ceramics, the future promises lighter, stronger, and more reliable solutions.

Kratos Glass is at the center of this transformation. By combining certified quality, global expertise, and cutting-edge research, it delivers transparent armor solutions that set new benchmarks for the defense industry. Whether for armored vehicles navigating conflict zones, naval craft patrolling contested waters, or command centers securing critical infrastructure, Kratos ensures that protection never comes at the cost of clarity.

In an era where every second and every decision matters, Kratos Glass provides not just armor, but the vision to stay ahead.

Tags: bulletproof glass manufacturer in USA, bulletproof glass manufacturer based in the UAE, laminated glass manufacturer in Canada, custom laminated glass manufacturers in UK, laminated glass manufacturer in Germany.